Cucumber Coating: Liquidseal can replace plastic packaging and keeping Cucumbers Fresh for Longer

Discover Liquidseal’s superior alternative to plastic. Our edible coatings provide a safe and effective solution to meeting the increasing demand for sustainable alternatives to macro-perforated plastic packaging. By offering all the same protective benefits as plastic without the harmful and polluting consequences to the environment, our coatings are a low-cost and superior alternative to plastic packaging.

Cucumbers Preservation and Shelf-Life

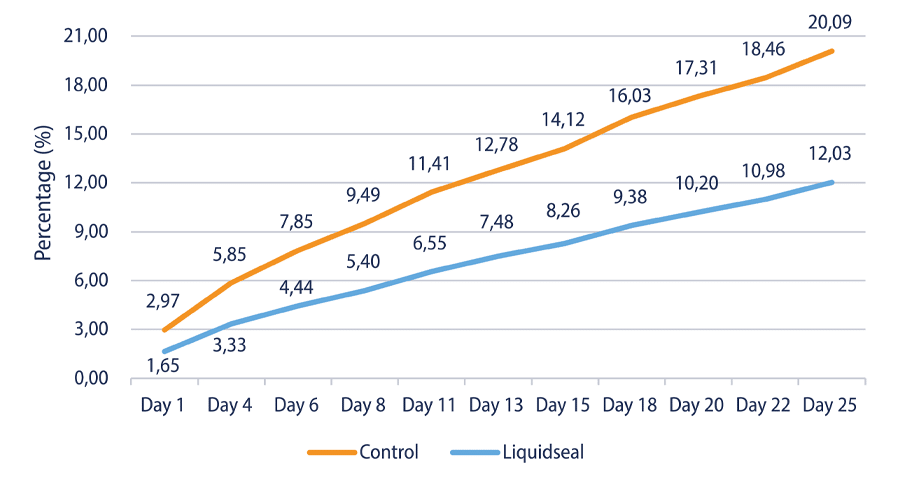

With Liquidseal’s cucumber coating, you can extend the shelf-life of cucumbers and maintain their quality. Our plant-based formula consistently retains the firmness of cucumbers, allowing them to enter their ripened stage while still staying fresh. Sealed cucumbers are less susceptible to contaminants like mold, and we have observed a significant reduction in weight loss.

Liquidseal for Cucumbers post harvest

Results after 25 days at room temperature

Average weight loss

Liquidseal: Respect for Products, Partners, and Our Planet

Liquidseal preserves precious global resources by preventing wastage. By making optimal use of water and fertile soil, we can extend the shelf-life of vegetables like cucumbers, but also of our planet. Global challenges have inspired us to step up and take the lead in moving our industry forward to a more sustainable future. Successful partnerships and a shared passion for excellence are what it will take to get things done.

Results: ECOLogic

Cucumbers coated with our innovative formula consistently retain a more constant quality and increased firmness. Results show better looking cucumbers that are less susceptible to contaminants like mold, as well as a significant reduction in weight loss.

Using Liquidseal cuts out food waste and plastic which allows us to meet the highest sustainability standards that today’s consumers have come to expect at an affordable and attractive rate for our partners across the supply chain!

Specially formulated coatings are used for both mini/snack cucumbers and Long English cucumbers to enhance the quality and prolonging the shelf-life.

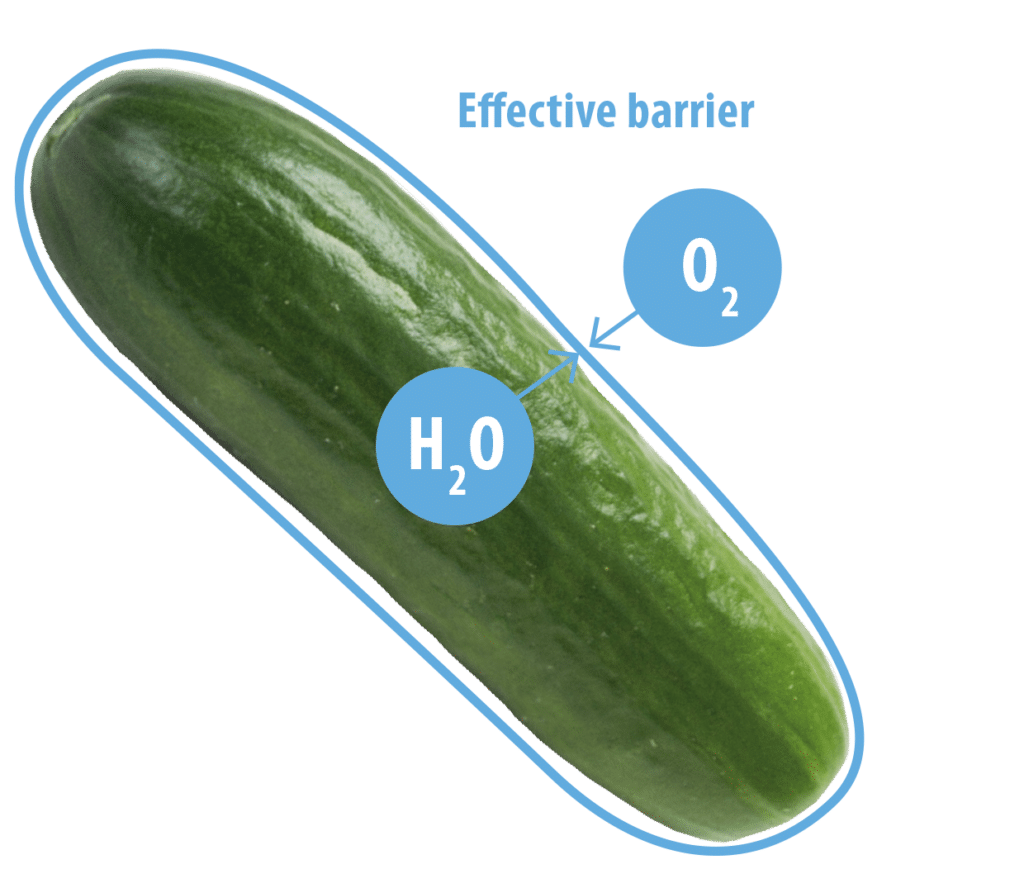

How it works

Liquidseal is a post harvest coating which achieves shelf-life extension of perishable products such as vegetables and fruits. Liquidseal preserves product quality and freshness from grower to customer.

Effective barrier:

- reduces evaporation

- slow release system

- controls gas exchange

Quality assurance

Liquidseal’s coatings meet GRAS standards. Our Premium product line is a food additive that is used on the surface of fruits with (in) edible peels. The intended use of the Liquidseal Premium coating complies fully with the FD&C Act and applicable food additive regulations when used as a coating on fruits and vegetables with inedible and edible peels.

“The edible coatings from Liquidseal have a positive effect on the shelf-life of (snack) cucumbers and are comparable to macro perforated packaging.”

– Product Specialist of an innovative cultivation business, the Netherlands.

From farm to customer, Liquidseal provides opportunities and benefits for all

Product Benefits:

- extends shelf-life

- reduces wastage

- no micro-plastics

- colour and texture preservation

- limits infections and cross contamination

- less weight loss

- maintains firmness

- hypoallergenic

Product Opportunities:

- reduces supply chain costs

- extends the sales window

- limits the use of chemicals

- opens up new markets

- alternative to plastic packaging

- provides greater flexibility in (sea) transportation

- complies with requirements of zero-tolerance countries

- sustainable solution for the market

The best time to start using Liquidseal was 10 years ago. The next best time is today.

Get in touch to learn more about Liquidseal’s eco-friendly protective coatings and how they can help take your business to the next level.

The Specifics

- Product name: Liquidseal for Cucumbers.

- Packaging: Jerrycan 25 ltr., Jerrycan 12,5 ltr., Drum 200 ltr., IBC 1.000 ltr..

- Shelf-life: 1 year (apply within 4 weeks after opening packaging).

- Storage: Minimum storage temp. 5 °C, maximum storage temp. 40 °C..

- Legislation: Compliant with FDA regulations.